Cellular Urethane Foam: High Resilience, High Rebound, and Versatile Application

Typical Properties of Style U-2626 Cellular Urethane Foam

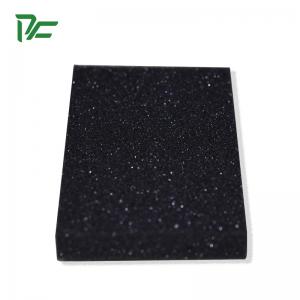

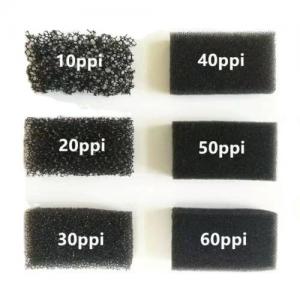

Description: U-2626 is a firm density Cellular Polyurethane Foam. This open cell sponge consists of ether polyurethane polymers. U-2626 and its family, have been specially developed for high resiliency and high rebound. This foam has a very low compression set, is breathable, dimensionally stable, and environmentally friendly. U-2626 meets the FMVSS-302 flammability rating, and has a temperature range of -40° F to 250° F, allowing it to be used in automotive applications.

U-2626’s excellent compression set characteristics and strength allow it to be used in many applications such as automotive, electronic, orthopedic goods, medical and safety equipment. Its low compression set makes it an attractive, economical choice for any application that requires a consistent thickness, such as spacers or fillers.

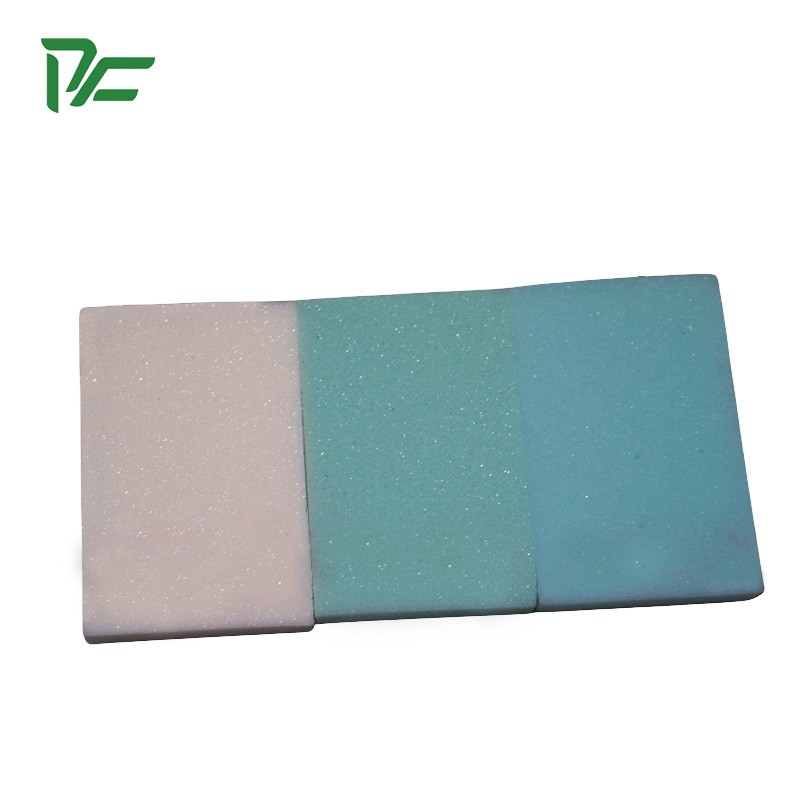

U-2626’s has a compression deflection @ 25% of 16 +/-4 psi, falling into the firm “4” Grade of ASTM D1056. Other grades can be softer or firmer, depending on application. All cellular urethane products can be supplied with or without adhesive backing in full rolls up to 60" wide, or slit rolls as narrow as ¼". We can also die cut or waterjet cut parts to your exact specifications.

| Polymer |

|---|

| POLYURETHANE |

| FLAMMABILITY SPECIFICATIONS | |

|---|---|

| FMVSS-302 | PASS (.063" OR THICKER) |

| Physical Property | Test Method | Unit of Measure | Result |

|---|---|---|---|

| COMPRESSION DEFLECTION @25% | ASTM D1056 |

psi kPa |

16.0 +/-4 110.3 +/-27.6 |

| DENSITY | ASTM D3574 |

pcf g/cm3 |

15.0 +/-2 .24 +/-.032 |

| 50% COMPRESSION SET (22 hrs. @ 730 F, 24 hrs. recovery) (MAXIMUM) | ASTM D 1056 | % | 3 |

| TENSILE STRENGTH (AVERAGE) | ASTM D3574 |

psi kPa |

130 896.3 |

| TEAR RESISTANCE (AVERAGE) | ASTM D624 |

lb./in kN/m |

14.5 2.53 |

|

ELONGATION (AVERAGE) |

ASTM D3574 | % | 145 |

| COMPRESSION FORCE DEFLECTION @ 25% | ASTM D3574 |

psi kPa |

10.3 71 |

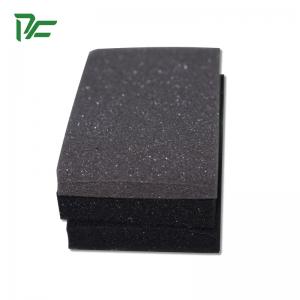

| COLOR | N/A | N/A | BLACK |