You’ve probably seen a lot of foam in your time. But what is polyurethane foam? It’s known by many names and is one of those things we take for granted – or ignore – every time we open a parcel or sit on a chair.

But you might be surprised just how many variations of polyurethane foam there are, as well as how it’s made. So here’s the quick summary, then we’ll get into more details…

The term polyurethane is also called PU, Urethane, or Reflex foam. It covers a range of foams that are synthesized using polyol and isocyanate. It is an open-cell foam, generally of medium to low quality, with a shorter lifespan than other foams, but a wide variety of uses.

Open-cell polyurethane foam has a number of pros, cons, and features associated with it. Here’s a list of what you can expect from polyurethane foam:

- Less-expensive

- Low to medium quality

- Low to medium density

- Soft texture and reasonably firm support

- Generally a shorter life span than other foams

- Fewer certifications

What is polyurethane foam – background

Polyurethane foam is a member of the leading wide-ranging and highly diverse family of “Polymers” or “plastics”. Polyurethane comes in two main forms; “closed” or “open: cellular structure.

It’s this (mostly) open-cell structure of Polyurethane that is widely regarded as Polyurethane foam.

Polyurethane foam is known by many names across the market. Some of which you may be familiar with and are as follows:

- Construction foam

- Door assembling PU foam

- Gap filling PU foam

- High Resilience foam

- Heat insulation PU foam

- Insulation foam

- High density foam

- Montage PU foam

- Mounting PU foam

- OCF PU foam sealant

- One component PU foam

- Polyurethane PU foam

- Sound isolation PU foam

- Window assembling PU foam

All these names are derived from the variances in how it’s processed, or what it’s specifically used for, and other specific properties added during processing.

Meaning these different names, in general, imply a specific type, form of use, or other special properties added to polyurethane foam.

You might call these “blends” of foam, and each manufacturer can create their own blend – to achieve specific purposes.

How polyurethane foam is made

There is a lot of science behind how polyurethane foam is made. It’s a complex process that frankly, only people in the industry would understand or want to know more about.

If you do want to know more, I’m sure there are expert chemists and websites far better able to explain that part than me. So I’ll stick with a simple description.

Polyurethane foam is made by reacting compounds of polyols and diisocyanates. Both these compounds are derived from crude oil. Blending these with viscose and other formulated chemicals creates a reaction that produces polyurethane.

The basic process of making polyurethane foam will include a series of other additives to produce various quality PU foam products.

The additives that are usually included are based on the application required of the foam, i.e. based on what the PU foam will be eventually be intended for.

The different names listed above are given for polyurethane, based on these variants. And each variant provides a specific purpose or application in the foam world.

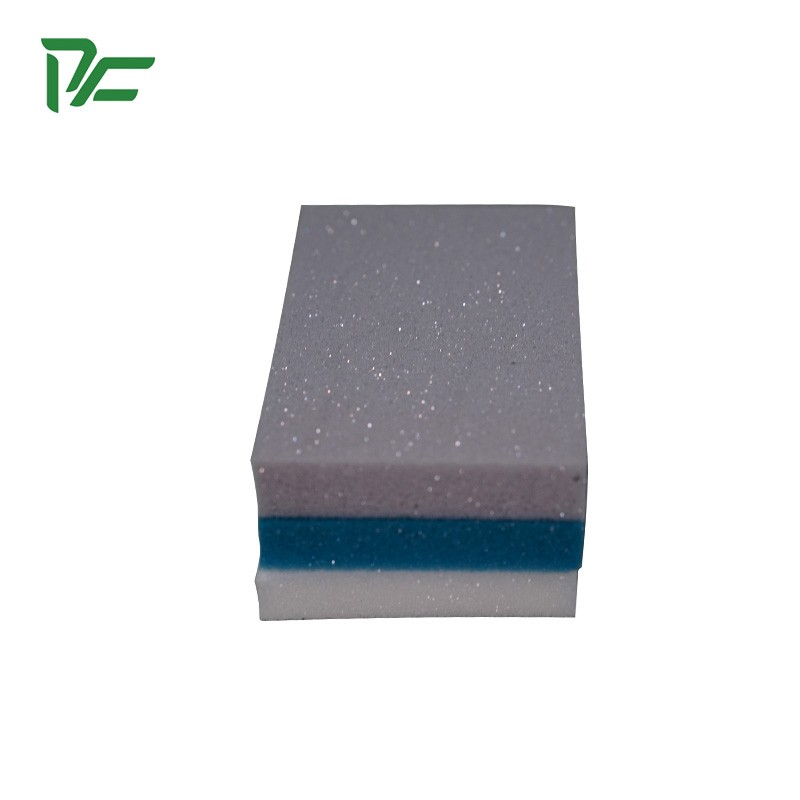

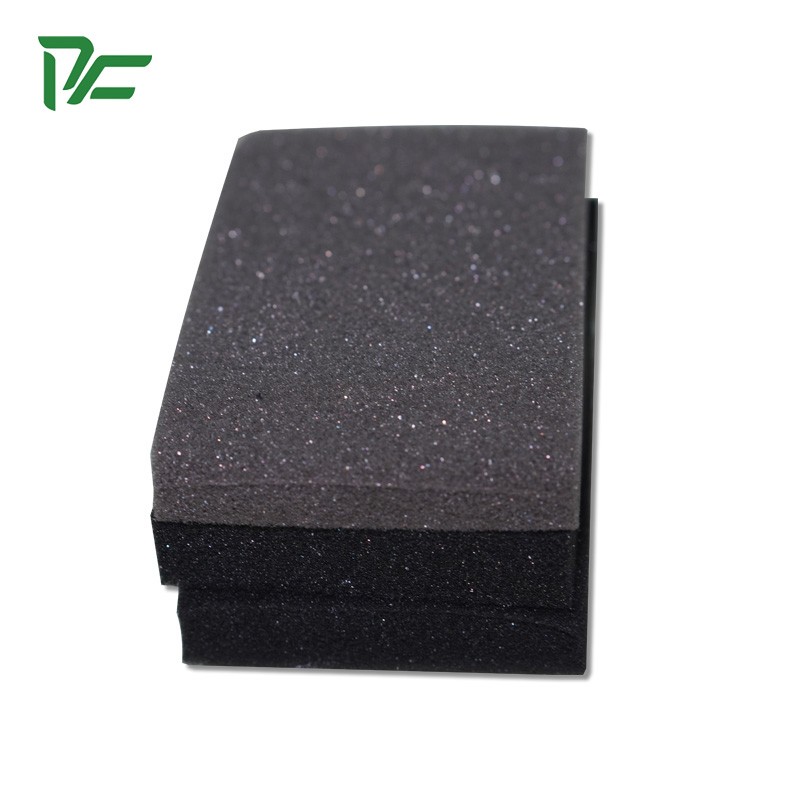

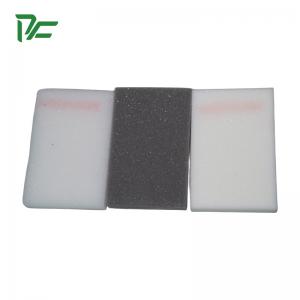

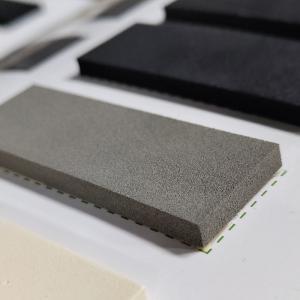

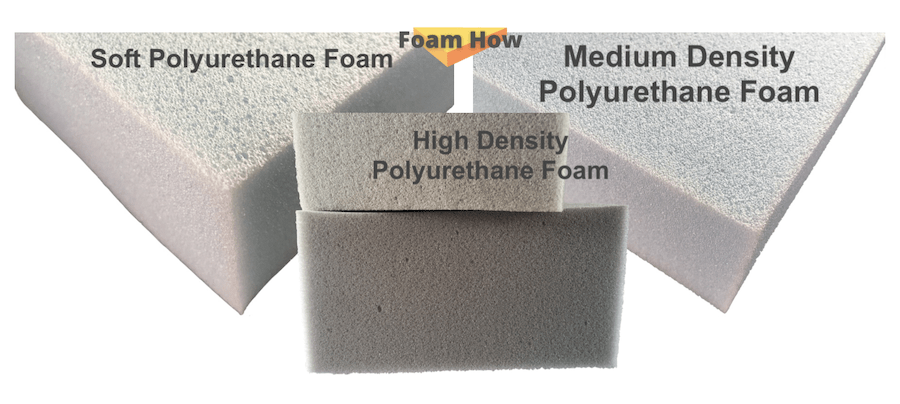

To provide some examples …below is a comparison photo of typical examples of open-cell soft, medium, and high-density foam. At first glance, they look largely the same, but at closer examination, you may be able to see that the cell structure becomes denser between soft and high.

Typical uses for polyurethane foam

Here are some of the typical environments in which you might find polyurethane foam.

- Lower quality mattress toppers

- Dog beds

- Packaging, shipping, and general filling

- Costumes and padding

- Furniture