Foam Material family is a HUGE group which can be categorized in many ways and types. For you easily, all foam materials can be either open cell foam or closed cell foam.

It might be complicated for you to learn what exactly they are in a short time. But after going through this post, you will easily find out what are open cell foam and what are closed cell foam. Another bonus is you can get to know the comparison between the 2 different types of foam material, and can choose wisely for your applications.

Foam materials are versatile, lightweight and durable, which makes them ideal for usage across many industries.

WHAT IS OPEN CELL FOAM?

Here we are going to elaborate open cell foam materials from some aspects in detail.

polyurethane foam is one of the most frequently-used open cell foams. They are widely used in insulation, sound and shock absorption application across a range of industries and materials, including furniture upholster, seat cushion, medical packaging, electronics, power equipment and so much more. Open cell Polyurethane Foams are superior to other forms of insulation for their dexterity and resistance to oxygen.

You might be puzzled to hear that something solid is also made of Polyurethane foam. The fact is actually that Polyurethane foam comes in two forms- open cell or closed cell structure, both of which differ in densities and respective applications. However, in this post, we focus on open cell Polyurethane foam materials.

Besides Polyurethane foam can also be provided in open cell structure. PVC/ Nitrile foam and EPDM foam rubber are available for open cell foams as well.

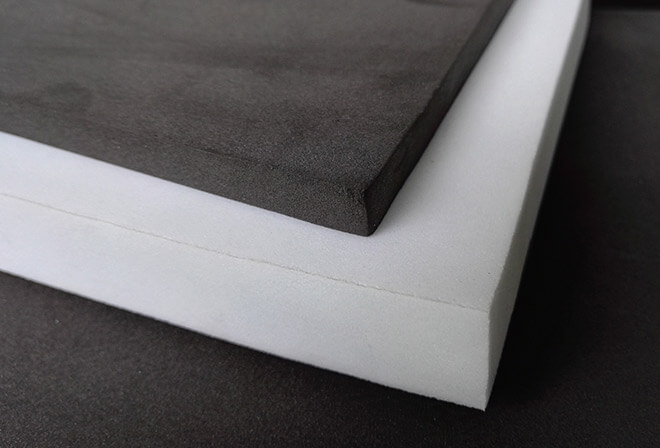

Open cell foams take Polyurethane foam sheets as an example where the cells within the material have been broken, allowing air to occupy the spaces within. Usually open cell foams are lightweight and less dense compared with closed cell foams, and they have a soft, cushioning and sponge-like appearance.

During an open cell foams expansion and curing, the gas bubbles used in its production are released into the atmosphere as against being locked in place as with closed cell foams. These holes within open cell foams enable them to interlock and interconnect. Due to this porous nature, open cell foams can not resist liquid water or water vapor.

WHAT ARE OPEN CELL FOAMS MADE OF?

There are an array of open cell foam materials, but generally they are made of Polyurethane, reticulated Polyurethane, PVC/ Nitrile, EPDM rubber etc..

FEATURES AND ADVANTAGES OF OPEN CELL FOAM

Some of the features and benefits of the open cell foam include:

-

It doesn’t contain any volatile organic compounds or ozone depleting gases

-

It is ideal for minimizing noise transmission

-

It produces little or no residual particles, and traps most foreign particles in its pore spaces, making it ideal for reducing dust and allergens

-

It is mold growth resistant

-

It is good at sound proofing

-

It has a good insulation value of approximately R-4.21 per inch

-

It accounts for about 40-50% of heat gain/loss in apartments

-

It is durable and will not break, shrink or diminish over time

-

It has a high expansion capacity, capable of expanding up to 100 times

-

It has a low density of between 0.4 and 1.2 lbs./ft3

USES OF OPEN CELL FOAM

Open cell foam can be used for a wide range of construction purposes including:

-

Low cost furniture upholster

-

Interior design projects

-

Sound proofing for buildings

-

Foam protective packaging

-

Vapor, moisture and air permeable required application

WHAT IS CLOSED CELL FOAM?

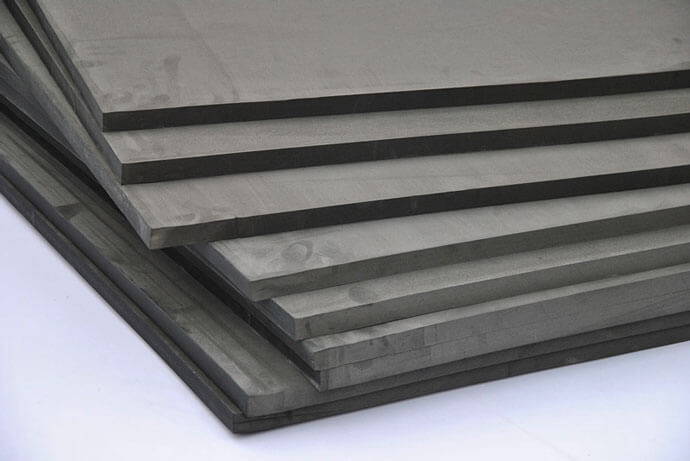

Closed cell foam is a strong, flexible plastic rubber material that’s made up of internal pores or cells. These internal cells of closed cell foam sit closely together but are not connected. Closed cell structure can be compared to a net filled with bubbles, where the balloons are trapped tightly against each other, but each of the bubbles are not interconnected.

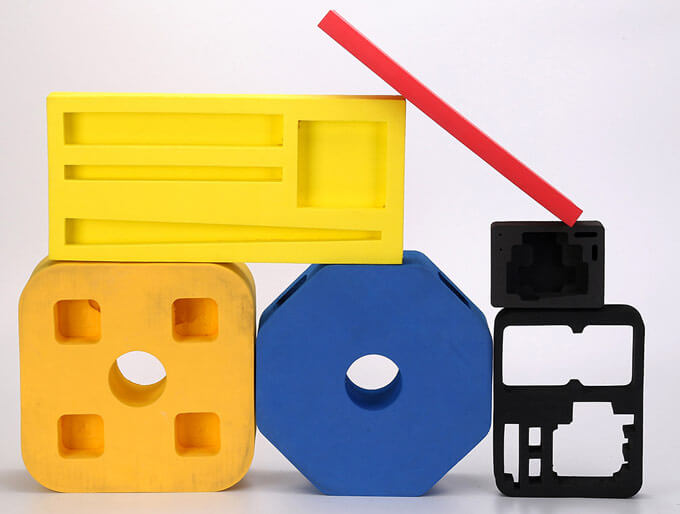

Also closed cell foams are more frequently used from various industries including construction, packaging, marine, electronics, automotive and so on. The typical closed cell foam materials include EVA foam material, Polyethylene foam, Neoprene foam, PVC/ Nitrile foam rubber, SBR foam rubber and so on.

WHAT ARE CLOSED CELL FOAMS MADE OF?

The materials which can be used to produce the closed cell foam vary greatly from EVA, polyethylene, polystyrene, rubber to polypropylene etc.. The closed cell foam principally contains trapped gas bubble which are formed during the expansion and cure of the foam. These bubbles constitute a blowing agent. They are permanently locked to a place, as the trapped gas is very efficient in increasing the insulation capability of the foam. The foam which is formed is strong and is usually of a medium density which enables the gas bubbles to lock into place. The nature of the foam enables it to be vapor retardant and resist liquid water.

FEATURES AND ADVANTAGES OF CLOSED CELL FOAM

The features and advantages of the closed cell foam include:

-

Helpful and extremely reliable to be used in both exterior and interior environments

-

Helpful in increasing the structural strength

-

Best for providing heat and sound insulation

-

Effectively Reduce the vapor transmission

-

Superior moisture barrier

-

Excellent resistance to leakage

APPLICATIONS OF CLOSED CELL FOAM

There are a lot of applications for the closed cell foam. They can be quite useful for a variety of application which requires moisture & shock resistance and heat & sound insulation. Closed cell foam as well as the sponge rubber products are extremely popular with the insulation, cushioning, padding and gasketing application for years. And the applications of closed cell foam are limitless. It is also used as a means of custom foam protective packaging which are used to safely store and present fragile jewelry, tools and electronics etc.. They offer excellent protective cushioning, moisture and air resistance as well, which prevents the moisture from gathering inside the package, making it the best choice for safely storing delicate machinery for longer period of time.

The typical applications for closed cell foam includes:

-

Insulation and sealing for construction and building

-

The appliances and HVAC system

-

Thermal insulation and shock absorption

-

The seals of enclosure and cabinets

-

The medical disposables

-

The equipment of gas and oil

-

Aerospace and aircraft

-

The transportation and automotive